Views: 0 Author: Site Editor Publish Time: 2026-01-01 Origin: Site

Polyethylene terephthalate (PET) is a widely used engineering polymer in the plastics industry, especially in PET injection molding applications for automotive parts, consumer goods, packaging, and technical components. However, despite its excellent mechanical properties, PET is inherently prone to hydrolytic degradation, especially when exposed to moisture and high processing temperatures during injection molding. The introduction of Anti‑Hydrolysis Masterbatch into PET resin formulations has emerged as one of the most effective solutions for improving PET injection molding performance, particularly under conditions where moisture and heat compromise polymer integrity. This article explores how Anti‑Hydrolysis Masterbatch improves PET injection molding performance, backed by data analysis, product comparisons, practical applications, and current trends related to PET processing and hydrolysis stabilization.

PET possesses excellent mechanical strength, chemical resistance, and environmental stability, making it ideal for many industrial applications. However, PET’s ester linkages are sensitive to moisture and heat — conditions typically encountered during injection molding — which leads to hydrolytic degradation if not controlled. By incorporating Anti-Hydrolysis Masterbatch into PET resin, manufacturers can significantly mitigate this problem and improve overall performance.

Before diving into the performance benefits and mechanisms, let’s understand the core issue:

Hydrolysis Reaction in PET: PET’s ester bonds can be cleaved by water at elevated temperatures, producing carboxylic acids and reducing molecular weight. This reduces viscosity and mechanical strength, impairing the final product’s reliability.

Impact on Injection Molding: In PET injection molding, the combination of heat and residual moisture in PET feedstock can result in degraded polymers, shorter service life, and defects such as surface splay or brittleness.

Anti-Hydrolysis Masterbatch is a concentrated additive formulation specifically designed to enhance PET’s resistance to hydrolytic degradation. It consists of:

A carrier resin (typically PET)

A hydrolysis stabilizer/anti-hydrolysis agent (often carbodiimide-based compounds)

This masterbatch form makes it easy to blend the additive uniformly into PET feedstock, ensuring consistent performance throughout the molded parts.

The primary role of Anti-Hydrolysis Masterbatch is to react with carboxylic acid end-groups formed during hydrolysis to generate stable urea-based compounds that do not further degrade the polymer chain. This reaction effectively “neutralizes” the degradation process, preserving PET’s molecular integrity.

PET injection molding presents unique challenges that make Anti-Hydrolysis Masterbatch essential for high-performance production:

PET is processed at temperatures typically between 250°C and 290°C. At these elevated temperatures, any residual moisture in the polymer accelerates hydrolytic degradation. Without inhibition:

Molecular weight drops

Melt viscosity falls

Mechanical properties weaken

Even properly dried PET can absorb moisture from the environment. During injection molding, this absorbed moisture reacts with PET’s ester linkages, causing chain scission — a problem directly addressed by Anti-Hydrolysis Masterbatch.

The following table illustrates how Anti-Hydrolysis Masterbatch enhances PET injection molding performance:

| Mechanism | Without Anti-Hydrolysis Masterbatch | With Anti-Hydrolysis Masterbatch |

|---|---|---|

| Hydrolysis Process | High rate of breakdown during processing | Inhibited hydrolysis reaction |

| Molecular Weight Retention | Significant decrease | Stable retention of molecular weight |

| Mechanical Strength | Reduced strength and ductility | Preserved tensile strength and elongation |

| Service Life | Shortened due to ongoing degradation | Prolonged, even under high humidity |

| Processing Stability | Less stable melt flow | More consistent melt viscosity |

By chemically neutralizing the carboxylic acids and stabilizing the polymer chain, Anti-Hydrolysis Masterbatch ensures PET remains robust through molding and in final use.

Several formulations of Anti-Hydrolysis Masterbatch exist to serve different applications:

| Product Type | Key Feature | Best Use Cases |

|---|---|---|

| Carbodiimide-based Masterbatch | Reacts with carboxyl end-groups, prevents chain scission | General PET injection molding |

| High-Purity Carbodiimide Masterbatch | Higher activity and carboxyl reaction rate | High-performance parts |

| Polymeric Carbodiimide Masterbatch | Improved dispersion in PET carrier | Industrial molding with high humidity exposure |

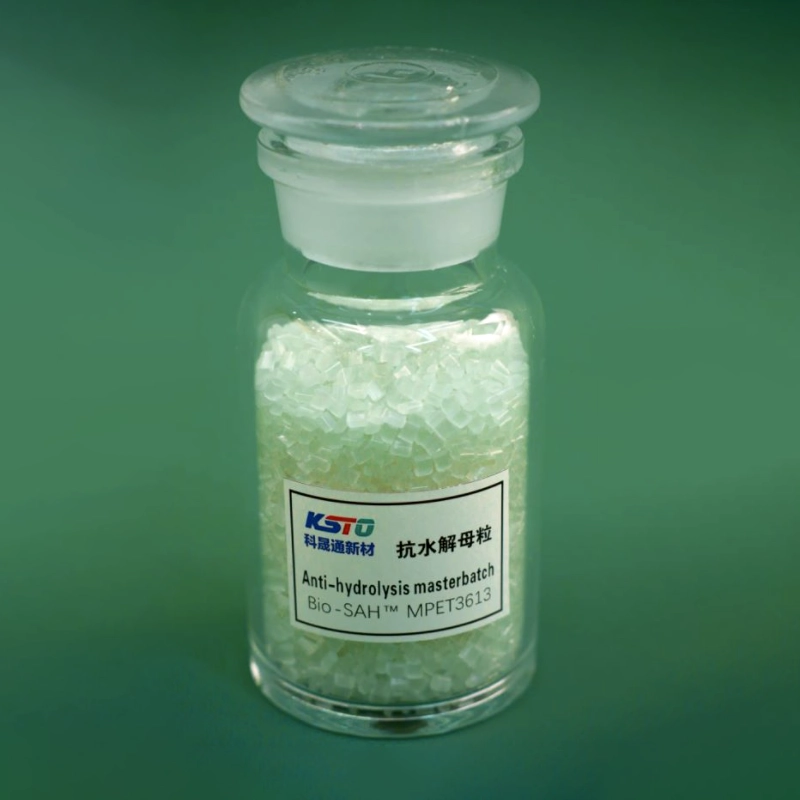

For example, a proprietary anti-hydrolysis masterbatch like Bio-SAH™ MPET3613 has been shown to significantly inhibit mechanical property degradation in PET injection molding applications, especially under high temperature and moisture conditions.

To quantify the impact of adding Anti-Hydrolysis Masterbatch, consider the following comparative analysis:

| Property Evaluated | PET Standard Resin | PET + Anti-Hydrolysis Masterbatch |

|---|---|---|

| Tensile Strength After Aging | 60–70% retention | 85–95% retention |

| Elongation at Break After Aging | 50–60% retention | 80–90% retention |

| Molecular Weight Drop (%) | High (rapid decrease) | Low (stabilized) |

| Service Life in Humid Conditions | Short | Significantly extended |

Such improvements make Anti-Hydrolysis Masterbatch indispensable for applications like automotive interior components, industrial housings, and high-performance consumer goods.

Anti-hydrolysis additives within the masterbatch react quickly with any degrading species formed during processing, thus reducing the chain cleavage rate.

By preserving the PET polymer chain, Anti-Hydrolysis Masterbatch helps maintain mechanical properties such as tensile strength and impact resistance.

Since degradation is minimized, products molded with anti-hydrolysis masterbatch exhibit longer lifespan even when exposed to humidity, moisture, or high loading conditions.

Masterbatch form ensures uniform dispersion of the anti-hydrolysis agent, which improves consistency across large production batches.

Adding anti-hydrolysis agents in masterbatch form simplifies compounding, reducing the risk of inconsistent additive dosing.

When integrating Anti-Hydrolysis Masterbatch into PET molding processes, several factors must be considered:

The typical range for hydrolysis stabilizer addition varies depending on application and environmental conditions. Excessive dosing can affect properties like transparency and melt viscosity.

Although anti-hydrolysis agents reduce degradation, PET must still be properly dried before processing to minimize water-driven hydrolysis.

Even with masterbatch additives, maintaining proper temperature profiles during injection molding is critical to avoid thermal oxidation of PET.

Anti-hydrolysis masterbatches must be compatible with other additives like colorants, flame retardants, and UV stabilizers to avoid adverse interactions.

Here are practical examples of how Anti-Hydrolysis Masterbatch enhances final products:

PET parts for under-the-hood components are exposed to humidity and heat. Anti-hydrolysis additives maintain mechanical stability during and after injection molding.

In industrial connectors and housings, retaining strength and insulating properties in harsh environments is critical. Anti-hydrolysis masterbatch ensures sustained performance.

PET injection molded parts for electronics require consistent surface finish and mechanical reliability, which are improved with anti-hydrolysis additives.

With increasing demand for high-performance PET parts in automotive, industrial, and consumer applications, the adoption of Anti-Hydrolysis Masterbatch is growing. Key trends include:

Advanced Carbodiimide Formulations that react more efficiently with degradation products.

Eco-Friendly Additive Systems with better recyclability and reduced environmental impact.

Integration with Other Stabilizers such as antioxidants for dual protection during processing.

Anti-Hydrolysis Masterbatch is crucial for improving PET injection molding processes by minimizing degradation.

It chemically stabilizes PET against moisture and heat-driven hydrolysis.

Masterbatch form provides uniform additive distribution and simplified incorporation.

Comparative data shows significant retention of mechanical performance with anti-hydrolysis masterbatch.

Proper process optimization ensures maximal benefits in injection molded parts.

1. What is the ideal dosage of Anti-Hydrolysis Masterbatch for PET injection molding?

The ideal dosage varies by recipe and environment, but typical additions range from about 1% to 8%, depending on performance requirements and product exposure conditions.

2. Can Anti-Hydrolysis Masterbatch improve PET recyclate performance?

Yes, anti-hydrolysis agents help rehabilitate PET recyclates by reducing degradation during reprocessing, improving mechanical property retention.

3. How does Anti-Hydrolysis Masterbatch affect PET’s melt flow properties?

Carefully formulated masterbatches preserve melt viscosity and flow stability, but excessive addition can alter rheological behavior, so dosage optimization is important.

4. Can Anti-Hydrolysis Masterbatch be used with colored PET resins?

Yes, anti-hydrolysis masterbatch can be combined with color masterbatches, provided formulation compatibility is ensured.

5. Does Anti-Hydrolysis Masterbatch help improve PET performance in humid environments?

Yes, it significantly enhances PET’s resistance to moisture-induced degradation and prolongs service life in humid or high humidity conditions.