Ultimate Polymer Protection Solution

Anti-Hydrolysis Agent Series

KSTO’s Bio-SAH™ anti-hydrolysis agents are specially engineered to combat polymer degradation caused by moisture, heat, and acidic by-products. Our portfolio includes monomeric and polymeric carbodiimide stabilizers in powder, liquid, aqueous emulsion, and masterbatch forms.

These agents react with carboxylic acids and water to form stable urea linkages, thereby preventing autocatalytic hydrolysis and extending polymer service life. Ideal for applications in polyurethane, polyester polyol, biodegradable plastics, and engineering resins, Bio-SAH™ provides long-lasting protection and enhances mechanical integrity.

Storage Conditions

Proper storage of anti-hydrolysis agents is crucial to maintain their efficacy and prevent degradation.

Recommended storage conditions include:

Temperature: Store in a cool, dry place, typically between 5°C and 35°C.

Packaging: Keep containers tightly sealed to prevent moisture ingress and contamination.

Avoid: Exposure to direct sunlight, heat sources, and humidity.

Wide Industry Applications

Polyurethane Products

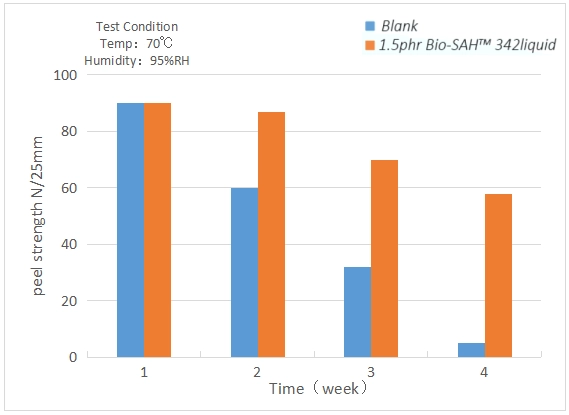

Used in TPU, CPU, adhesives, and PU sole materials, Bio-SAH™ prevents hydrolytic breakdown under humid and high-temperature conditions. Enhances lifespan by 1–3 times.

Biodegradable Plastics (PLA, PBAT)

With only 0.3–0.5% dosage, Bio-SAH™ boosts hydrolysis resistance by up to 7 times in PLA, making it viable for packaging, agriculture, and medical uses.

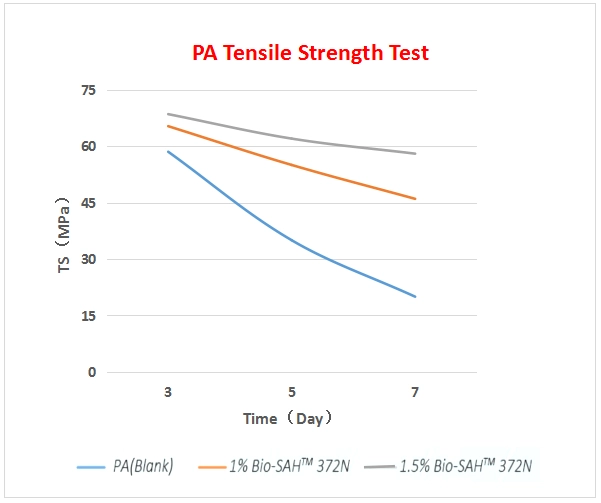

Engineering Plastics (PET, PBT, TPEE)

Improves acid value and thermal resistance during processing. Maintains strength and dimensional stability under continuous stress and heat.

Polyester Polyol Systems

Bio-SAH™ reacts with terminal carboxylic groups and neutralizes acids generated during extrusion, preventing molecular weight loss and increasing processing safety.

Key Product Benefits

Reliable, safe, and easy-to-use additives that extend polymer lifespan and improve mechanical stability under extreme environmental conditions.

Superior Hydrolysis Resistance

Bio-SAH™ stabilizers chemically bind with carboxylic acids and water, halting autocatalytic hydrolysis. This ensures the polymer retains its mechanical properties even in high-heat, high-humidity environments. The result is a 2–3 times increase in material longevity for demanding applications like elastomers and specialty films.

Easy Processing and Versatility

Offered in various forms—powder, liquid, and masterbatch—Bio-SAH™ integrates seamlessly into existing processes. Compatible with polyurethanes, PET, PLA, and nylon systems, it also improves processing safety by neutralizing reactive by-products during extrusion and molding.

High-Purity, Color-Safe Reactivity

Bio-SAH™ 362 is a monomeric carbodiimide with >99.5% purity (GC), light color and no odor, delivering high activity at low dosage. It caps carboxyl end groups and scavenges moisture, stabilizing polyester and polyurethane systems without discoloration. With a 50–53 °C melting point and soluble in organic solvents (insoluble in water), it integrates into coatings, adhesives, elastomers and lubricating oils for consistent, high-quality results.

Latest Industry Updates

-

Empowering Material Upgrades, Building Industrial Resilience - Suzhou Keshengtong New Materials Technology Co., Ltd. Invites You to the 21st China International Polyurethane ExhibitionThe performance breakthrough of polyurethane materials is inseparable from the technological innovation of core addi

Empowering Material Upgrades, Building Industrial Resilience - Suzhou Keshengtong New Materials Technology Co., Ltd. Invites You to the 21st China International Polyurethane ExhibitionThe performance breakthrough of polyurethane materials is inseparable from the technological innovation of core addi

Common Questions

Q1: How do anti-hydrolysis agents work?

A1: They react with carboxylic acids and water, forming stable urea compounds to stop hydrolytic chain scission.

Q2: Which materials benefit from Bio-SAH™ agents?

A2: TPU, CPU, PET, PLA, PBT, nylon, polyol, EVA, and many biodegradable plastics.

Q3: How much Bio-SAH™ should I use?

A3: Dosages typically range from 0.3% to 2.0%, depending on material and performance goals.

Get in Touch Today

Have questions about our products? We're here to help!

Mob:+86-512-66706407

E-mail:service@kstoantihydro.com